Dadri, Gautam Buddha Nagar, Uttar Pradesh

- GST NO. : 09ARCPD4541L1ZS

View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | NST |

| Condition | New |

| Power Source | Electric |

| Click to view more | |

Product Details

Certification

ISO 9001:2015

Voltage

220V

Warranty

1year

Country of Origin

India

Model Number

NST-SC1

Motor

24VDC, Brushless, 200 W Max.

Net Weight

25 Kg

Compliance

CE Certified

Spin Coater Size

25.2cm(Φ) x 41cm(H)

Digital Controller Size

23cm(L) x32cm(W) x16cm(H)

Payment Terms

L/C, T/T, Western Union

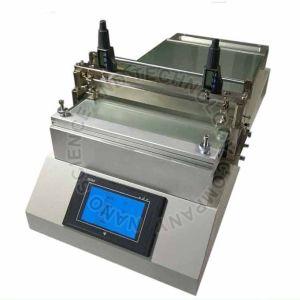

Anti-Corrosion Spin Coater ( 8000 RPM & 6″ wafer Max.) with Complete Accessories

Structure

- Case and spin disk made of Polypropylene (PP) to resist most of the corrosive solutions.

- Digital control box is separated from spin coater.

- One filter is included in standard package. It is used to connect the pump and coater for preventing waste water from flowing into the pump.

Input Power

- Default 220VAC, 50/60Hz, single phase, 1000W Max.

- 110V is available in optional bar ( with 1500W transformer )

- A power socket on the back of the Digital control box is used to supply power to the vacuum pump. (The output voltage of this power outlet depends on the input voltage of the spin coater, e.g. if the spin coater is plugged into AC 110V, this power socket will supply AC 110V.)

Chamber & Vacuum Chuck

- Chamber diameter: 150 mm

- PP anti-corrosive vacuum chuck Φ100mm, which can hold substrate upto 6″ Dia.

- If your sample < 10 mm, please order rubber cup from us at extra cost

Vacuum Pump

- One 120L/min Oilless Vacuum Pump is included in the standard package, please click the picture below for specification details.

- For Ar glove box user, we recommend our 24VDC vacuum pump for simple pump and coater connection with no feedthrough required.

Spin Speed

- Digital control panel with six programmable segments of different spin times and speeds

- Maximum programmable spin time 6*60s = 360s

- 500 – 8000 RPM adjustable spinning speed at each segment

Liquid Injecting

20mL syringe is used to contain the coating material

Optional

- You may choose Precision Electronic Single Channel Pipette: 20 – 200uL for more accurate coating

- Using plasma cleaner to treat substrate surface before coating can improve film quality

- Heating cover with digital temperature controller up to 120 ℃ is available upon request at extra cost ($1950), which allow sample drying in-situ during and after coating

- Vacuumable spin coater with digital gauge is available

Warranty

- One year limited with lifetime support.

- Rusting and damage due to improper storage condition or maintenance are not covered by warranty

Looking for "NST-SC1 Anti-Corrosion Spin Coater" ?

Piece

Explore More Products